In munda weindasitiri yealuminium alloys,1070 aluminium mahwendefa anomirasemumiriri wepakati wepamusoro kuchena kwealuminium mhinduro, yakagadziridzwa zvakanangana nemamiriro ezvinhu apo magetsi conductivity, ductility, uye kugadzikana kwemakemikari zvinoiswa pamberi. Yakarongerwa pasi peiyo 1000 yakatevedzana (yekutengeserana yakachena aluminium), 1070 inonyatso kuenderana nezviyero zvakaita seASTM B209 (Standard Specification yeAluminium neAluminium Alloy Sheet uye Plate) uye EN 573-3, ine mashoma aruminiyamu emukati e99.70% akakosha maitiro akakonzeresa kukonzeresa kutadza kukonzeresa. Kusiyana neakakwirira-simba 7000-akatevedzana kana akasiyana 6000 akateedzana alloys, 1070 inogara pane yakakosha mukana we "kuchena-inotyairwa kushanda": iyo mishoma yealloying zvinhu uye yakasimba yekusachena kutonga inoita kuti ive sarudzo yakanaka yekutonga kwekupisa, kufambisa kwemagetsi, uye nemazvo ekugadzira mamiriro ezvinhu, zvinobudirira zvemagetsi zvinodiwa, kuzadzisa zvinodiwa nevatengi muchikamu chekuvaka. yakakwirira-yakavimbika, inodhura-inoshanda yakachena aluminium zvinhu.

1. Kuumbwa Kwemakemikari: Nheyo yeKuchena uye Kusagadzikana

Kuita kwe1070 aluminium plates kunotarirwa neayo e-ultra-high aruminiyamu yemukati uye inodzorwa tsvina dzakasimba. Segiredhi rearuminiyamu rekutengeserana rakachena, kuumbwa kwayo kunorerutswa nemaune, iine chete trace alloying zvinhu zvinowedzerwa kukwenenzvera processability pasina kukanganisa kuchena. "Kureruka" uku hakusi kuganhurirwa asi dhizaini yakanangwa kuchengetedza zvimiro zvealuminium (semuenzaniso, conductivity, corrosion resistance) kuti ienderane nemamiriro anoda kuchena kwezvinhu.

Core Kuumbwa: Ultra-Yakakwira Aluminium Yemukati

- Aluminium (Al): ≥99.70% - Sechikamu chikuru, ndiyo musimboti weiyo 1070's siginecha zvivakwa: yakanakisa thermal/electric conductivity, natural corrosion resistance, uye superior ductility. Kuchena kwepamusoro kunovimbisa kuita kusingachinjiki pabatch yega yega, iyo isinga taurike inodiwa yezvishandiso zvakaita semagetsi mabhazi emagetsi uye chaiyo yekupisa kupisa.

Kunodzorwa Kusachena uye Trace Elements

Kusachena kwemukati kunongogumira kudzivirira kukanganisa conductivity, ductility, kana pamusoro pemhando. Zvinoenderana neASTM B209 uye EN 573-3 zviyero, miganho yakakosha ndeiyi:

- Simbi (Fe): ≤0.25%. Kusachena kwakanyanya mualuminium; simbi yakawandisa inoumba yakaoma intermetallic komisheni (semuenzaniso, Al₃Fe), iyo inoderedza kusimba kwezvinhu uye kuramba. Kudzora simbi yemukati pazasi 0.25% inoita kuti 1070 aluminium mahwendefa haatsemuka panguva yakadzika yekudhirowa, kukotama, kana mamwe maitiro ekugadzira.

- Silicon (Si): ≤0.10%. Trace silicon inoderedza kupisa conductivity uye inogona kukonzera kuremara kwepamusoro panguva yeanodization, saka kudzikamisa kwakasimba kunodiwa.

- Mhangura (Cu): ≤0.03%, Manganese (Mn): ≤0.03%, Zinc (Zn): ≤0.03%. Aya matrace elements anenge abviswa zvachose, sezvo kunyange mari shoma inogona kuderedza magetsi conductivity (yakakosha kune conductive application) uye kuwedzera pitting corrosion ngozi.

- Zvimwe Zvimiro: ≤0.15% muhuwandu. Kusanganisira titanium (Ti) yekunatsa zviyo uye kutsvaga magnesium (Mg), inowedzerwa muhuwandu hudiki chete panguva yealuminium plate rolling process kukwirisa mashandiro pasina kushandura masikirwo emhando yealuminium yakachena.

2. Maitiro Ekuita: Iyo Yakakwana Musanganiswa weDuctility, Conductivity, uye Workability

Zvakanakira 1070 mahwendefa ealuminium anotarisa pane "kuumbwa" uye "kuchena kwakavakirwa kushanda" pane kusimba kwepamusoro kuchiisa parutivi kubva kune alloyed aruminiyamu zvinhu. Kuita kwayo kunowedzera zvakanakira mabhenefiti ealuminiyamu yakachena, ine zvigadziriso zvakanaka kuburikidza nekudziya (kupisa kurapwa kana kutonhora kushanda) kuenderana nemhando dzakasiyana dzekugadzira zvinodiwa. Kusiyana nema alloys anopira ductility yesimba, 1070 inobata chiyero pakati pekuita uye kuvimbika, ichiiita "inosiyana-siyana yakachena aluminium zvinhu" kune ese ari maviri kugadzirisa uye nemazvo ekugadzira mamiriro.

Mechanical Performance: Ductility seCore

Michina ye1070 inosiyana zvishoma nekutsamwa (semuenzaniso, Temper O yekuzadza zvizere, Kupisa H14 yekushanda kuri pakati nepakati kutonhora), asi hunhu hwayo hwepakati nguva dzose hunoenderana ne "kuumbwa kuri nyore":

- Kusimba Kwesimba (σb): 70 ~ 110 MPa. Yakaderera pane yakasanganiswa aruminiyamu (semuenzaniso, 6061 ine simba rekusimba re276 MPa), asi inokwana kune isiri-yakarongeka application senge yekurongedza uye yekushongedza mapaneru.

- Goho Simba (σ0.2): 30 ~ 95 MPa. Kuderera kwegoho simba rinoreva zvinhu zvinokotama uye kutambanudza zviri nyore, zvichiita kuti zvive zvakanaka pakudhirowa kwakadzika (semuenzaniso, aluminium cookware) kana kugadzira roll (semuenzaniso, mavhavha emagetsi).

- Elongation paKuzorora (δ): 10 ~ 35%. Exceptional ductility (kusvika 35% yeTemper O) inobvumira kuti iumbwe kuita ma geometries akaoma pasina kutsemuka-mubairo usingaenzaniswi nemamwe simbi dzakachena semhangura.

- Brinell Kuoma (HB): 15 ~ 30. Kuomarara kuri pakati nepakati kunogonesa kugadzirisa kuri nyore (semuenzaniso, kuchera, kucheka) uchiramba madiki makwara panguva yekushandiswa (semuenzaniso, yekushongedza trim).

Kuita Kwenyama uye Kwezvakatipoteredza

Zvimiro zvemuviri zve1070 ndiwo masimba ayo makuru emakwikwi, yakatorwa zvakananga kubva kune yakakwira aluminium yemukati:

- Thermal Conductivity: 235 W/(m·K). Pedyo neiyo yealuminiyamu yakachena (237 W/(m·K)), ichiiita imwe yemaindasitiri aruminiyamu alloys ane yakanakisa kupisa kupisa kuita. Inokodzera mamiriro akadai senge LED kupisa sinks, zvemagetsi mudziyo dzimba, uye kupisa kunopisa.

- Electrical Conductivity: 61% IACS (International Annealed Copper Standard). Kupfuura akawanda aruminiyamu alloys (semuenzaniso, 6061 ine conductivity yemagetsi ye43% chete IACS), zvichiita kuti ive sarudzo yakanaka kune zvinhu zvemagetsi zvakaita semabhasi, tambo, uye capacitor housings.

- Corrosion Resistance: Yakanakisa (Natural Passivation). Iyo yakakwira aluminium yemukati inoumba dense oxide firimu (Al₂O₃) pamusoro, kudzivirira imwe oxidation. Kusiyana nearuminiyamu yakasanganiswa, 1070 haidi yakawedzera kukoira yekudzivirira ngura mukati memukati kana munyoro wekunze nharaunda (semuenzaniso, yekuvaka trim).

- Density: 2.70 g/cm³. Yakakosha lightweight mukana (30% yakareruka kupfuura mhangura), kuderedza mari yezvinhu uye uremu hwekuisa. Yakakodzera kurema-sensitive scenarios akadai semotokari kupisa nhovo uye aerospace mukati mezvikamu.

Kugadzirisa Kuita: Nyore Kugadzira uye Mutengo Wakaderera

Kupfava uye ductility ye1070 inoita kuti ive "processing-hushamwari" aluminium zvinhu, kupfupisa kutenderera kwekugadzira uye kuderedza mitengo:

- Formability: Zvakanaka. Inogona kumira maitiro akasiyana-siyana akadai sekudhirowa kwakadzika, kuumba roll, kukotama, uye kutenderera pasina kutsemuka. Semuenzaniso, inowanzoshandiswa kugadzira zvigaba zvearuminiyamu zvisina musono kana mapaneru ekushongedza akakomberedzwa.

- Weldability: Zvakanaka. Inopindirana nezvose zvakajairwa aluminium welding process (semuenzaniso, MIG welding, TIG welding, resistance welding) ine kushoma post-weld cracking, iyo yakakosha kune hombe dzakaunganidzwa senge kupisa exchanger cores.

- Kurapa Kwepamusoro: Inokodzera Multiple Kupedzisa Maitiro. Inoita zvakasarudzika muanodization (yakasikwa / yemavara), poda coating, uye electroplating. Kusachena kwayo kwakaderera kunovimbisa yunifomu, isina gwapa, inonyanya kukosha kune zvidimbu zvekushongedza (semuenzaniso, fenicha trim) kana zvikamu munzvimbo dzakanyanya kukora (semuenzaniso, mavharivha emagetsi emugungwa).

- Machinability: Zvakanaka (neSpecialized Tools). Izvo zvinhu zvakapfava, zvinogonesa kukurumidza kugadzirisa, asi mafuta anodiwa kudzivirira "galling" (zvinhu zvinonamatira kukucheka maturusi). Inokodzera zvikamu zvakanyatsoita semagetsi ekubatanidza uye sensor housings.

3. Application Scope: Purity Driven Cross Industry Solutions

Nekusanganiswa kwayo kwe "kuchena kwepamusoro & kushanda kwepamusoro,"1070 mahwendefa ealuminium avechinhu chinofanirwa-kuva nemaindasitiri umo "kuita kunotsanangurwa nekuchena." Idzi dzinotevera dzepakati nzvimbo dzekushandisa dzakanyatsoenderana neayo mabhenefiti ekuita, inovhara akasiyana siyana kubva kuhupenyu hwezuva nezuva kusvika mukugadzirwa kwemaindasitiri:

Electronics uye Electrical Engineering

Iyo indasitiri yemagetsi inodiwa ye1070 inotarisa pane yayo conductivity uye yekupisa manejimendi kugona:

- Electrical Busbars. Inoshandiswa mumagetsi ekugovera masisitimu (semuenzaniso, mafekitori, nzvimbo dzedata) kufambisa mafambiro akakwira zvakanaka. Yayo 61% IACS conductivity inodzikisira kurasikirwa kwesimba, nepo ductility yayo ichibvumira tsika kukotama kuti ikwane nzvimbo dzakasimba.

-Kupisa Sinks uye Thermal Interface Zvikamu. Inoshandiswa mu LEDs, CPUs, uye magetsi amplifiers. Kupisa kwayo kwe235 W/(m·K) kunokurumidza kubvisa kupisa, kudzivirira chikamu chekupisa uye kuwedzera hupenyu hwebasa.

- Capacitor uye Battery Housing. Kuramba kwayo kwegora uye kuchena kwakanyanya kunodzivirira kuita kwemakemikari ne electrolytes, kuve nechokwadi chekuvimbika kwenguva refu kwevatengi vemagetsi (semuenzaniso, mafoni) uye mabhatiri emaindasitiri.

Packaging uye Consumer Goods

Iyo ductility, kuchena, uye kuchengetedzwa kwechikafu kwe1070 kunoita kuti ive chinhu chakakosha muindasitiri yekurongedza:

- Chikafu-Giredhi Aluminium Foil Composites. Inoshandiswa mukurongedza kuchinjika (semuenzaniso, snack wrappers, zvinwiwa makadhibhokisi). Kuchena kwayo kwepamusoro kunodzivirira kusvibiswa kutama kupinda muchikafu, nepo ductility yayo ichibvumira kutenderera kune yakanyanya-mutete makobvu (kudzika kusvika 0.005 mm) pasina kubvaruka.

- Cookware uye Tableware. Yakagadzirwa kuita isingaremi, yakaenzana-inobatisa kupisa hari, mapani, uye mapepa ekubikira. Kuramba kwayo kwechisikigo kushatisa kunobvisa kudiwa kwejasi rine muchetura, zvichiteerana nezviyero zvekuchengetedza chikafu chepasi rose (semuenzaniso, FDA, EU 10/2011).

- Aerosol Cans. Yakagadzirwa mumakani asina musono kuburikidza nekudhirowa kwakadzika kwezvizoro, zvigadzirwa zvekuchenesa, uye mishonga. Ductility yayo inovimbisa yunifomu inogona madziro ukobvu, nepo kushora kwayo kunodzivirira zviri mukati kubva mukusvibiswa nesimbi.

Kuvaka uye Architectural Design

Muzviitiko zvekuvaka, zvakanakira 1070 zviri mune yayo aesthetics, corrosion resistance, uye formability:

- Decorative Panels uye Trim. Mushure mekuputira anodize kana hupfu, anoshandiswa kushongedza mukati / kunze (semuenzaniso, kuvaka facade, fenicha mipendero). Iyo yunifomu yepamusoro kupedzisa uye yakapfuma sarudzo dzemavara inosimudzira kukwezva kwekuona.

- Heat Reflective Panels. Yakaiswa mudenga kana madziro ekudzivirira masisitimu. Iyo yakakwenenzverwa nzvimbo ine kupisa kunoratidza inopfuura 80%, kuderedza kupisa kwezuva kunyura uye kudzikisa mutengo wesimba rekuvaka.

- Electrical Conduits. Inoshandiswa pakudzivirira waya muzvivako zvekutengesa. Kuramba kwavo kwecorrosion kunovimbisa kusimba munzvimbo dzine hunyoro kana dzine guruva, nepo dhizaini yavo isingaremi ichirerutsa kuisa.

Maindasitiri uye Aerospace Sectors

Kunyangwe mune zvinorema maindasitiri mamiriro, 1070 inoita basa rakakosha mune zvisiri-zvimiro zvikamu:

- Heat Exchanger Cores. Inoshandiswa mumaindasitiri chillers uye mota dzeHVAC masisitimu. Iyo yekupisa kwayo conductivity uye weldability inogonesa kutamisa kupisa, nepo dhizaini yayo isingaremi inoderedza huremu hwese.

- Aerospace Interior Components. Inoshandiswa mu cabin trim, marongero ekutakura mikwende, uye maenclosure emagetsi. Kuchena kwayo kunoenderana neaerospace zvinhu zviyero (semuenzaniso, AMS-QQ-A-250/1), uye kushora kwayo kunoenderana nekushisa uye hunyoro shanduko mucabin.

- Precision Instrument Housing. Inoshandiswa semasensa, midziyo yekuyeresa, uye midziyo yemurabhoritari. Yayo yakaderera tsvina yemukati inodzivirira electromagnetic interference (EMI), kuve nechokwadi chekuverenga chiridzwa chakaringana.

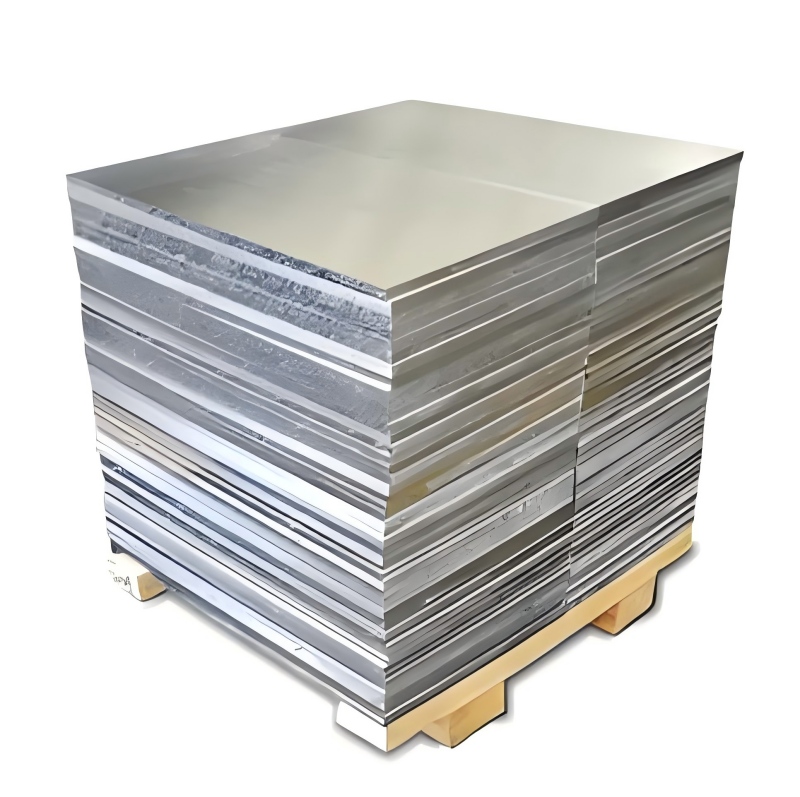

Kudyidzana Nesu Yemhando yepamusoro 1070 Aluminium Plates

Shanghai Miandi Metal Group Co., Ltd. inyanzvi mukugadzira 1070 aruminiyamu ndiro dzinosangana dzakaomarara pasi rose zviyero (ASTM B209, EN 573-3, AMS-QQ-A-250/1). Isu tinoshandisa yakakwirira-kuchena aruminiyamu ingots (Al content ≥99.70%) uye advanced rolling tekinoroji kuti ive nechokwadi cheuniform plate ukobvu (0.2 mm–50 mm) uye yakanakisa yemhando yepamusoro. Batch yega yega inogona kupa Material Test Certificates (MTC) uye wechitatu-bato bvunzo mishumo. Tichivimba nemakumi emakore ekugadzirwa kwesimbi, isu takavaka yakazara-cheni sevhisi kugona inovhara R&D, kugadzira, kugadzirisa, uye kuyedza. Zvigadzirwa zvedu zvinotengeswa kumba nekune dzimwe nyika, zvichishandira maindasitiri epamusoro senge aerospace, mota, semiconductors, uye simba idzva.

Isu tinogona kupa zvigadziriso zvakagadziridzwa kuti zvizadzise zvaunoda chaizvo:

- Tsika Saizi: Akashongedzerwa nehunyanzvi hwekucheka michina, tinogona kuita hutsinye uye hwakatsetseka kugadzirisa pazvinhu zviri mukati me2600 mm, tichipa akachekwa-kusvika-kureba mahwendefa kana yakazara-hupamhi mahwendefa (yakanyanya hupamhi 2000 mm) zvinoenderana nezvinodiwa, kuderedza marara emidziyo;

- Kurapa Kwepamusoro: Isu tinopa anodization (yakasikwa / yeruvara), poda yekuputira, uye yekupolisha masevhisi ekuvandudza aesthetics uye kusagadzikana kwemarara, kuchinjira kune yekushongedza uye yakakwirira-kuora nharaunda zvinodiwa;

- Precision Machining: Iine 14 vertical machining centers, 2600 mm gantry machining centers, uye JDMR600 5-axis high-speed machining centers, tinogona kuwana composite processing yakadai sekugaya, kugaya, kuchera, kufinha, uye kubata, nekugadzirisa machining ± 03 mm. Isu tinokwanisa kugadziridza mabhara emagetsi eindasitiri yemagetsi, kugadzira giredhi-giredhi yezvikafu zvisina kujairika midziyo yeindastiri yekurongedza, uye kugadzira yakagadziridzwa kupisa inovhenekera mapaneru echikamu chekuvaka, kuendesa zvakagadzirira-ku-kumisa zvikamu zvakapedzwa zvakananga.

Kunyangwe iwe uri mugadziri wemagetsi anoda yakakwirira-conductivity aluminium, bhizinesi rekurongedza rinotsvaga chikafu chegiredhi rekudya, kana kambani yekuvaka iri kutsvaga zvekushongedza.aluminium 1070 aluminium mahwendefaisarudzo yepamusoro-soro, yakavimbika-yakavimbika. Bata nesu nhasi kuti tikumbire tekinoroji data sheets, samples, kana customized makotesheni, uye rega Shanghai Miandi Metal Group Co., Ltd. ikubatsire kushandura "kuchena" kuita "kuita."

Sarudza 1070, Sarudza Shanghai Miandi Metal Group Co., Ltd.

Nguva yekutumira: Nov-17-2025