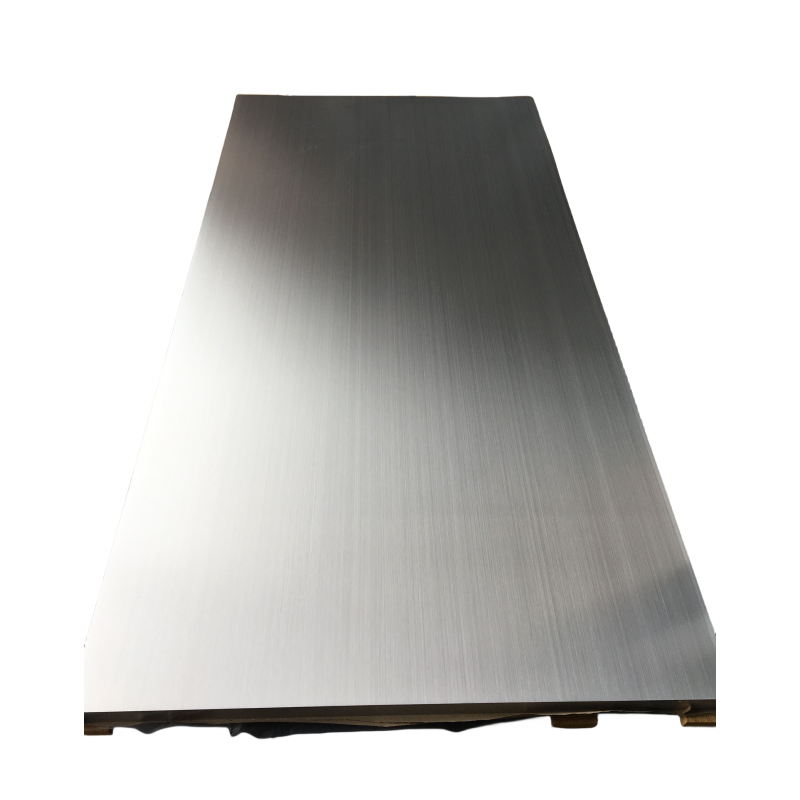

Mukati menzvimbo yakakura yearuminiyamu alloys, 6061 inomira pachena seyekutanga sarudzo yealuminium plate application inoda kuenzana kwesimba, machinability, corrosion resistance uye weldability. Kazhinji inopihwa muT6 temper (mhinduro yakagadziriswa kupisa uye yezera rekugadzira),6061 aluminium ndiro inoparobust mechanical properties zvichiita kuti ive yakakosha mumaindasitiri asingaverengeki. Kunzwisisa maitiro ayo uye mikana yetsika machining kiyi yekuvhura kugona kwayo kuzere kweprojekiti yako.

Core Properties & Metallurgy ye6061 Plate

6061 ndeye6000 akateedzana aruminiyamu alloys, anonyanya kusanganiswa nemagnesium (Mg) uye silicon (Si). Musanganiswa uyu unoumba iyo intermetallic compound Mg2Si, inokonzeresa kuwedzera kwesimba reiyo alloy kuburikidza nekuoma kwemvura panguva yekupisa kweT6. Zvinhu zvakakosha zvinosanganisira:

1. High Strength-to-Weight Ratio: 6061-T6 ndiro inopa inoshamisa kusimba simba (kazhinji 45,000 psi / 310 MPa min) uye goho simba (40,000 psi / 276 MPa min) uchichengetedza density inenge chikamu chimwe muzvitatu chesimbi. Izvi zvinoita kuti ive yakanaka kune lightweight structural components

2. Excellent Machinability: 6061 inozivikanwa nokuda kwepamusoro machinability pakati pekupisa-anopisa aluminium alloys. Inogadzira machipisi akachena, inobvumira kumhanya kwekucheka kwakakwira, uye inowana yakanakisa kupedzisa kwepamusoro neakasiyana CNC machining mashandiro (kugaya, kutendeuka, kudhirowa, kubaya). Izvi zvinoderedza zvakanyanya mari yekugadzira uye nguva yekutungamira.

3. Yakanaka Corrosion Resistance: Iyo inogadzika aluminium oxide layer inopa kuchengetedzwa kwemukati kune ngura yemhepo. Kuita kunogona kuwedzeredzwa kuburikidza nekurapa kwepamusoro seanodizing (Rudzi rwechipiri kana hardcoat - Rudzi rwechitatu), chromate conversion coating (semuenzaniso, Alodine) kana poda coating.

4. Weldability:6061 ndiro inoratidzira yakanaka weldabilitykushandisa maitiro akajairika seGasi Tungsten Arc Welding (GTAW/TIG), Gasi Metal Arc Welding (GMAW/MIG) uye Resistance Welding. Post-weld kupisa kurapwa kungave kuri madikanwa kudzoreredza simba rakazara munzvimbo yakakanganiswa nekupisa (HAZ) yezvikumbiro zvakakosha.

5. Formability: Kunyange zvazvo isina kuumbwa se 5000 series aruminiyamu alloys mune annealed (O) mamiriro, 6061-T6 ndiro inogona kupinda pakati pekugadzira maitiro. Kune maumbirwo akaomarara, kazhinji zviri nani kuita muchina kubva muplate stock.

6. Moderate Thermal Conductivity: Inobatsira pakushandisa senge masingi ekupisa uye zvikamu zvinoda kumwe kupisa.

Zvinonyanya Kushandiswa zve6061 Aluminium Plate

1. Aerospace & Aviation: Zvigadzirwa zvendege, mbabvu dzemapapiro, fuselage zvikamu, zvigadziriso zvemuchadenga (zvisingakoshi), gearbox housings. Simba rayo uye kureruka kwayo ndizvo zvakakosha.

2. Kutakura & Motokari: Chassis components, mabhureki, mashizha ekumisa, mibhedha yerori yakajairwa, trailer frames, bhatiri yakavharidzirwa yeEVs. Inobata vibration uye stress zvakanaka.

3. Marine: Zvikepe zvezvikepe & decks (kunyanya crafter diki), masts, hatch mafuremu, fittings. Inotsamira pakupokana nekuora (kazhinji kunowedzerwa).

4. Industrial Machinery & Robotics: Machine frames, varindi, magumo ekupedzisira, maoko emarobhoti, jigs uye zvigadziriso, gear housings. Benefits kubva machinability uye rigidity.

5. Structural & Architectural: Bridge decking, walkways, platforms, facades yekuvaka, mapurisa ekushongedza, masitepisi. Inopa kusimba uye yemazuva ano aesthetics.

6. Consumer Goods & Recreation: Bicycle frames & components, musasa wemisasa, zvikamu zvekamera, zvinhu zvemitambo, zvivharo zvemagetsi emagetsi emagetsi.

7. General Fabrication: Matangi & midziyo (ye-non-corrosive media), mabheji, mahwendefa anokwira, prototypes, tsika dzemabhureki & mapaneru.

Tsika Machining ye6061 Plate: Apa ndipo panonyatso penya 6061. Kuita kwayo kunoita kuti ive iyo inosarudzika substrate yekunyatso machining kuita yakaoma, yakakwirira-kushivirira zvikamu. Key kugona zvinosanganisira.

1. CNC Milling: Kugadzira yakaoma 2D uye 3D profiles, homwe, slots, uye contours. Yakanakira prototyping uye yakaderera-kusvika-yepakati vhoriyamu kugadzirwa inomhanya.

2. CNC Turning: Kugadzira cylindrical parts, flanges uye zvinhu zvinoda kutenderera symmetry kubva paplate stock.

3. Drilling & Tapping: Kugadzira chaiwo makomba mapatani uye maburi ane threaded yekuungana.

4. Kucheka: Waterjet kucheka (inotonhora nzira, hapana HAZ), laser cutting (high precision, minima kerf), plasma cutting (inokurumidza, mahwendefa akakora), uye tsika dzemasaha.

Kupedzisa Beyond inoshanda machining, kuwana yaunoda aesthetics uye inokwidziridzwa zvivakwa kuburikidza ne:

Michina Inopedzwa: Se-yakagayiwa, yakakweshwa, yakakwenenzverwa.

Anodizing: Inowedzera corrosion / abrasion kuramba, inobvumira kufa kwemavara (architectural anodizing).

Chemical Conversion Coatings: Kuvandudza kunamatira kwependi uye kushomeka kwekudzivirira (eodine).

Painting & Powder Coating: Yakasimba, yekushongedza inopera mune chero ruvara.

Media Blasting: (semu, sandblasting, bead blasting) yekugadzirwa kana kugadzirira pamusoro.

Tight Tolerances: vane ruzivo machinist vanogona kubata zvakanyanya dimensional kushivirira pane 6061 plate zvikamu.

Prototyping to Production: Inokodzera kune imwe-kure prototypes kuburikidza nepamusoro-vhoriyamu yekugadzira machining.

6061 aluminium plate, kunyanya muT6 temper, inomiririra mhinduro yakakwana yeinjiniya apo simba, uremu hwekuchengetedza, kugadzira uye kusagadzikana kwekuora zvinosangana. Mhinduro yaro yakasarudzika kuCNC machining inopa vagadziri uye mainjiniya kuti vagadzire zvakanyanya kuomarara, chaizvo, uye zvinhu zvakavimbika zvinobudirira. Kunyangwe iwe uchida ndiro yakapfava yekumisikidza, yakaomesesa dhizaini bracket, kana inyanzvi yemhepozvikamu, 6061 ndiro, nyanzviyakagadzirwa uye yapera, inopa kushanda kwakafanana uye kukosha.

Nguva yekutumira: Jun-25-2025